Staying on top of the ever-changing logistics and supply chain management landscape is a key to success. Get the latest warehouse management system (WMS) software installed to avoid future troubles.

This also enables you to speed up your own operations and run things more efficiently. Travelling with your vehicle does not just mean you move from one place to another in your car.

This guide will look at the latest innovations in the WMS program, the prime specifications to be on the lookout for, and the methods of selecting the most suitable set of technology which will serve your requirements.

Key Takeaways

- Up-to-date WMS considerably improves stock balances as well as order shipping quality.

- Main aspects entail the availability of cloud-based options, advanced analytics, and integration of IoT.

- The pros are productivity, better clients’ relationships, and the amount of money saved.

- Prospective innovations entail AI, blockchain, sustainable practices, and AR.

- Picking the best WMS consists of correct need assessment, investigation of the alternatives and guarantee that the systems can be extended.

Why Modern WMS Is Critical

Modern WMS is much more than inventory tracking. It represents an end-to-end solution that integrates quite well with other systems to give real-time data for optimal decision-making.

- Increased accuracy of inventory.

- Improved order fulfillment rates.

- Real-time visibility into warehouse operations.

- Integration with the rest of the business systems, such as ERP and CRM.

Implementation of a warehouse management system dramatically enhances stock accuracy because most of the tracking is automated, thus reducing manual errors. This improves the order fulfillment rate since accurate inventory levels will ensure that orders can be picked, packed, and shipped in good time.

Real-time visibility into warehouse operations allows managers to make informed decisions, thus optimizing the processes and reducing delays.

Modern WMS also offers the requisite integration capability with other business systems, such as ERP and CRM, providing one platform for improved overall business operations.

Key Features of Latest WMS Software

1. Cloud-Based Solutions

Besides flexibility and remote access for easier management across multiple locations with continued changing business requirements, cloud-based WMS eliminates expensive hardware and makes it easy to update and maintain. Scalability assures continued performance and reliability as your business grows.

2. Advanced Analytics and Reporting

Use data to seek insights into operational efficiencies and areas of improvement. Advanced analytics reports the exact inventory levels, order processing times, and overall warehouse performance.

Such data-driven insights enable managers to make proactive decisions for the optimization of resources, efficiency enhancement, and betterment of operations.

3. Automation and Robotics Integration

Integrate with automated systems and robotics to drive picking, packing, and shipping. Automation tames the quantity of manual labor involved and trim down errors, besides enhancing the speed of processing times on orders.

Integration of robotics takes it a bit further down in efficiency, handling the workers’ repetitive tasks to give humans more time for higher-level activities.

4. Mobile Access and Applications

This provides real-time updates and easier management on the go. Mobile-friendly interfaces, therefore, allow warehouse managers to access critical information, track inventory, or handle operations from any location using their mobile devices.

This, in turn, enhances flexibility and ensures that problems are resolved in good time, even when managers are not present at a site.

5. IoT and RFID Technology

Track inventory and assets efficiently in real-time across their lifecycle using IoT devices and RFID tags. On the other hand, IoT devices can provide precise, real-time data regarding the location and condition of an inventory item.

At the same time, RFID tags are fast and accurate in reading items. This step improves inventory accuracy, reduces loss, and increases operational efficiency in general.

Advanced WMS—Benefits of Implementation

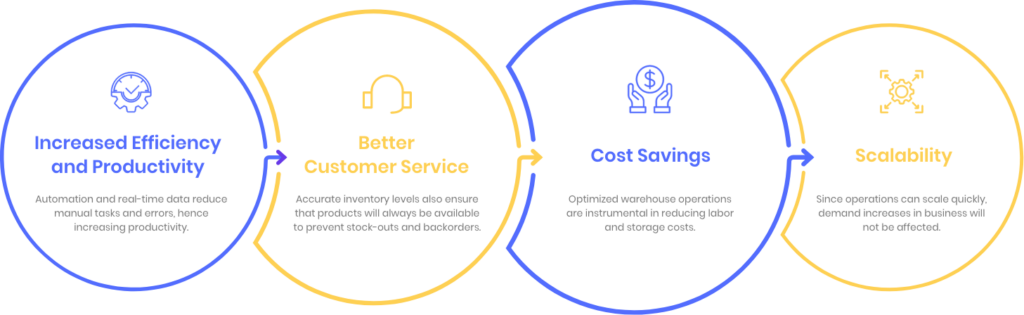

1. Increased Efficiency and Productivity

Automation and real-time data reduce manual tasks and errors, hence increasing productivity. Through a WMS, inventory tracking, order picking, and shipping are automated to take minimal time and less effort. Accordingly, this places first the order fulfillment time and, secondly productivity.

2. Better Customer Service

Faster, more accurate order fulfillment means increased customer satisfaction. Receiving orders on time and as ordered increases the customer experience and builds trust in your brand. Accurate inventory levels also ensure that products will always be available to prevent stock-outs and backorders.

3. Cost Savings

Optimized warehouse operations are instrumental in reducing labor and storage costs. Automation reduces the need for manual labor, while efficient space utilization cuts down storage costs. Other than that, it provides accurate inventory tracking, reducing excess inventory and bringing down holding costs, thereby minimizing waste.

4. Scalability

Since operations can scale quickly, demand increases in business will not be affected. A modern WMS should not slow down because order volumes increase or new locations are added.

This scalability ensures that your warehouse operations can handle any business growth by maintaining efficiency and productivity.

Trends That’ll Shape the Future of WMS

1. Artificial Intelligence and Machine Learning

AI and ML are changing WMS through predictive analytics and advanced automation capabilities. These can work within the warehouse to forecast demand, optimize inventory levels, and automate the most challenging tasks, increasing efficiency and accuracy even more.

2. Blockchain Technology

It has increased transparency and security of any supply chain-related transactions. With the application of blockchain technology, all transactions are recorded in an immutable ledger, noting the movement of every inventory in a transparent way. This improves trust and security within supply chain operations.

3. Sustainable Practices

One focus area of Green WMS solutions is the reduction of environmental impact by efficiently using available resources. This seeks to encompass sustainable practices related to energy usage, waste, and environmentally friendly packaging. These efforts have a positive effect not only on the environment but also on each company in terms of branding and customer loyalty.

4. Augmented Reality (AR)

AR tools can help train and solve problems now facing the warehouse in real-time. AR can provide visual overlays to workers to guide them through complex tasks, hence improving accuracy and reducing training time. Smooth warehouse operations require improved productivity and reduced errors.

Experience the simplest inventory management software.

Are you ready to transform how your business does inventory?

How to Choose the Right WMS for Your Business

1. Assess Your Needs

First off, evaluate where your processes are and begin to identify areas that must be improved. Some examples could be inventory accuracy and order fulfillment times; other operational efficiencies may differ. Knowing exactly what you need will help in picking a WMS to solve your issues.

2. Research and Compare Options

Look for systems that offer all the features you want, then compare their capabilities in several areas, such as ease of use, integration, and vendor reputation. Doing extensive research will ensure a WMS that best serves your requirements and builds long-term value.

3. Consider Integration Capabilities

Integrate the WMS with your previously installed systems. Smooth integration of WMS into ERP, CRM, and other business systems is critical to smoother operations. It integrates data across systems for a single platform in managing the warehouse.

4. Evaluate Vendor Support

Consider the support and training levels that this vendor will provide. Support and training are thus acutely critical to successful WMS implementation and long-term use. Seek out vendors that have comprehensive training, reliable support, and continued product updates toward peak performance.

5. Plan for Scalability

Choose a WMS that’s sure to grow with your business. Scalability means that when you gain more volumes, places, and new business requirements, the system will still work for you. This future-proofs a business’s warehouse operations by making sure that the WMS in use will keep up with evolving business needs.

Conclusion

State-of-the-art management system software future-proofs the warehouse; this is an imperative need if a business wants to remain competitive in today’s dynamic market. Modern WMS solutions help drive enhanced operational efficiency, cost reduction, and increased customer satisfaction. The right WMS will not only make your present operations seamless but also future-proof your warehouse to handle upcoming challenges and opportunities.

Ready to transform a warehouse?

While we encourage our customers to pursue solutions from multiple WMS providers, including PackemWMS, the principal target should be a system that best fits your needs for the successful implementation of this system shortly.