To optimize inventory management and streamline operations, warehouses have turned to advanced technologies like RF scanners. We will explore the significance of them in warehouses, their benefits, and how they are transforming the industry.

Looking for an Inventory management tool for Shopify? checkout WMS for Shopify

What Are RF Scanners?

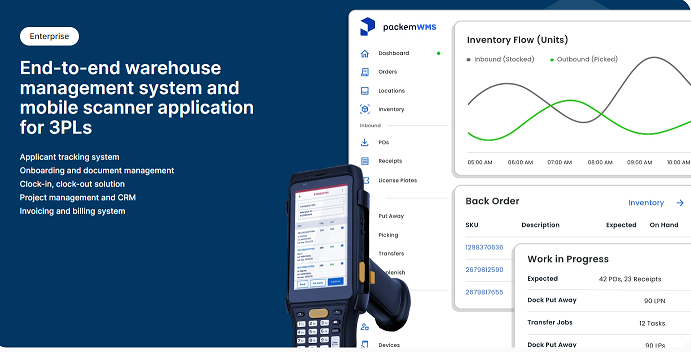

RF (Radio Frequency) scanners are handheld devices used in warehouses to capture and transmit data wirelessly. They operate on radio waves, allowing warehouse personnel to quickly and accurately gather information about inventory items, locations, and movements.

These “handy” devices are equipped with barcode scanning capabilities, enabling them to read barcodes on products and shelves, as well as RFID tags, if implemented.

Some of the commonly used methods are during Smart Picking and Packing for orders, Replenishment from bulk storage, and Cycle Count.

RF Scanners In Warehouse Operations

Efficient inventory management is the backbone of successful warehousing operations. Manual methods of inventory tracking are time-consuming and prone to errors, leading to delays, and inaccurate stock counts. Barcode Scanners address these challenges by automating the data collection process, providing real-time visibility, and enhancing overall operational efficiency.

Streamlined Receiving And Put-Away Processes

When products arrive at the warehouse, they need to be accurately logged into the inventory system and placed in the appropriate locations. RF scanners expedite this process by allowing workers to scan barcodes or RFID tags on incoming items, instantly updating the inventory database.

With real-time information, the warehouse team can correctly assign locations for storage, reducing errors and improving overall productivity.

Precise Picking And Order Fulfillment

Picking and order fulfillment are critical stages in warehouse operations, and accuracy is paramount. Barcode scanners empower workers to accurately locate and pick items by scanning barcodes on product labels or shelf locations.

By verifying the correct item and quantity in real-time, it significantly reduce the risk of errors, ensuring that the right products are picked and packed for each order. This streamlines the fulfillment process, minimizes returns, and enhances customer satisfaction.

Inventory Accuracy And Cycle Counting

Maintaining accurate inventory levels is essential for efficient supply chain management. RF scanners enable warehouses to conduct regular cycle counts, which involve counting a subset of items in the inventory. B

y scanning barcodes or RFID tags on randomly selected items, RF scanners quickly update the database with accurate stock counts. This ensures the inventory records align with the physical stock, enabling proactive inventory control and minimizing stock outs or overstock situations.

Real-Time Data Visibility And Reporting

These devices provide real-time data visibility, allowing warehouse managers to monitor operations and make data-driven decisions. The scanned data is wirelessly transmitted to the warehouse management system (WMS) or enterprise resource planning (ERP) system, providing instant updates on inventory levels, order statuses, and overall warehouse performance.

Managers can generate comprehensive reports and analyze key metrics, such as order accuracy, picking rates, and inventory turnover, to identify areas for improvement and optimize processes.

Experience the simplest inventory management software.

Are you ready to transform how your business does inventory?

Benefits Of RF Scanners In Warehouses

The integration of RF scanners in warehouse operations offers numerous benefits that contribute to improved efficiency, accuracy, and profitability

Increased Productivity: eliminate manual data entry and automate inventory processes, allowing workers to complete tasks faster and with fewer errors.

Enhanced Accuracy: With real-time scanning and validation, they reduce data entry errors, improving inventory accuracy and order fulfillment precision.

Improved Efficiency: By streamlining processes and reducing time spent searching for items, RF scanners enable warehouses to handle higher volumes of orders and reduce operational bottlenecks.

Real-time Visibility: provide instant access to up-to-date inventory data, allowing managers to make informed decisions, and allocate resources effectively.

Cost Savings: By minimizing errors, and improving overall efficiency, RF scanners contribute to cost savings in labor, inventory holding, and customer satisfaction.

Conclusion

In summary, RF scanners have become an indispensable tool in modern warehouse operations. These handheld devices revolutionize inventory management by automating data capture, enhancing accuracy, and improving overall efficiency. With real-time visibility and streamlined processes, warehouses can meet the demands of today’s fast-paced supply chains while reducing costs and improving customer satisfaction. Embracing RF scanners is a strategic move for warehouses looking to remain competitive and stay ahead in the dynamic world of logistics.

Try out PackemWMS 3PL Warehouse Manager for yourself, get in touch with our team, and request a free demo today.