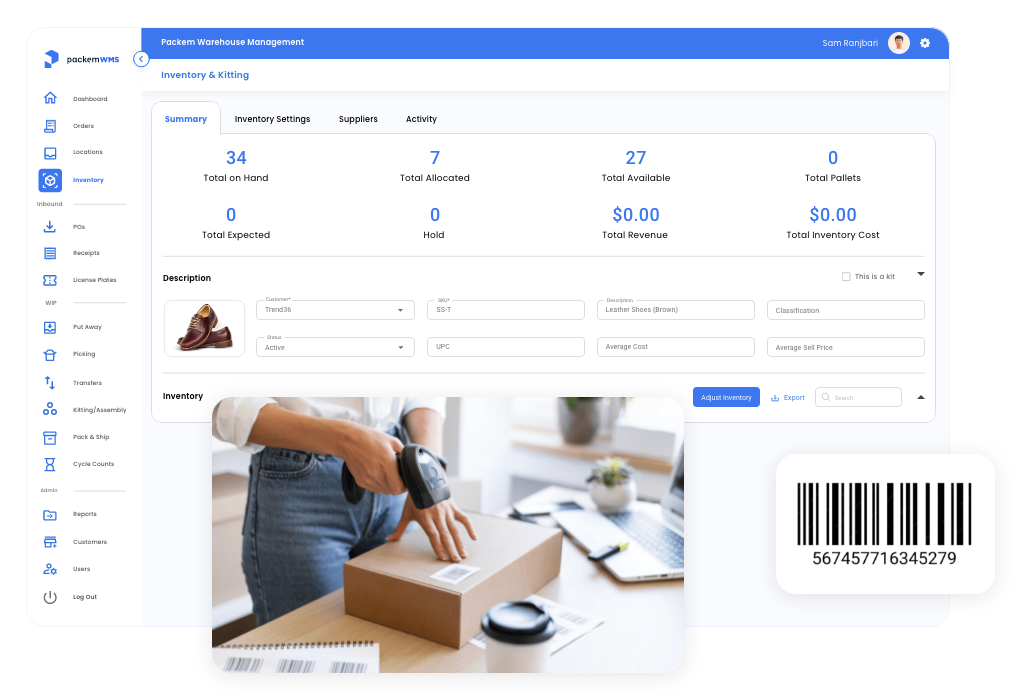

Live Inventory On Hand And Allocated: Keeping Your Pulse On Product Availability

The concept of ‘live inventory’ has transformed how businesses approach stock monitoring. Live inventory on hand refers to the real-time tracking of available stock within a warehouse or storage facility. This dynamic snapshot allows businesses to know exactly what is on hand at any given moment, enabling prompt decision-making related to sales, restocking, and customer service.

Allocated inventory, on the other hand, includes products that are committed to orders but have not yet left the warehouse. This distinction is crucial as it prevents the all-too-common problem of overselling, which can tarnish customer relationships and brand reputation.

Modern inventory solutions like PackemWMS connect directly to your one or many Shopify stores to automatically download orders for fulfillment and to sync available inventory across all stores.

How Inventory Software Makes A Difference

Modern inventory software seamlessly integrates these two concepts, offering a unified view that ensures accuracy and efficiency. It dynamically updates inventory levels with each sale or return, allowing product sellers to have up-to-the-minute data. Moreover, advanced analytics can forecast demand, making inventory management proactive rather than reactive.

Location Tracking of Products: Every Item, Every Time

Location tracking is an essential feature of warehouse management systems. In sprawling warehouses, time spent locating items is time lost, and in the world of commerce, time is indeed money. Inventory solutions now provide detailed location tracking of products, down to the aisle, rack, and bin so you can guide the picker directly to the location with enough quantity to fulfill orders.

By tagging inventory with barcodes or RFID tags, inventory software can track products’ movements throughout the warehouse, leading to more efficient storage methods and quicker retrieval times. This granularity not only improves internal operations but also enhances customer satisfaction with faster shipping times.

The Wonders of PO Management and Packing Slips

Purchase Order management is another critical aspect of inventory solutions. PO management tools within inventory software allow for the creation, approval, and tracking of purchase orders all within a single platform. This centralized approach reduces paperwork, eliminates data entry errors, and speeds up the ordering process from suppliers.

Packing slips, documents that accompany shipped goods, list the items included in a shipment. Inventory software that automates the creation of packing slips ensures that the right products with the right quantities are received at the warehouse to speed up receiving and quality control.

Paperless Picking: A Game-Changer in Warehouse Operations for Brands and 3PLs

Gone are the days when pickers roamed warehouse aisles with clipboards. Right? 🙂 Paperless picking, facilitated by scanners and mobile devices, is a game-changer. With this technology, the picking process is more accurate and significantly faster.

Inventory software integrates with handheld scanners, guiding warehouse staff through optimized picking routes and reducing the chance of human error. Items are scanned and automatically marked as picked in the system, updating inventory levels in real time and streamlining the entire process from shelf to shipment.

Implementing Inventory Solutions: A Strategic Approach

Implementing these advanced inventory solutions requires a strategic approach. Here are key steps for product sellers looking to modernize their inventory management:

- Evaluate Your Needs: Before selecting an inventory management system, evaluate your current processes and identify areas that need improvement. Consider the size of your inventory, turnover rate, and any specific challenges you face.

- Choose Scalable Software: Opt for inventory software that can grow with your business. Scalability ensures that as your product range and order volumes increase, your system can handle the expansion without requiring a complete overhaul.

- Integrate Systems: For maximum efficiency, integrate your inventory management system with other business systems, such as accounting software (QuickBooks or Xero) and e-commerce platforms. This creates a cohesive ecosystem that streamlines operations across all departments.

- Train Your Team: Any new system comes with a learning curve. Invest in comprehensive training for your team to ensure they can leverage the new inventory solutions effectively.

- Monitor and Adapt: Once implemented, closely monitor the new system and be willing to adapt your processes as needed. Regularly review the data provided by your inventory software to make informed decisions and continuous improvements.

In Conclusion: Empowering Product Sellers Through Technology

Inventory solutions, equipped with features for live inventory management, location tracking, PO management, and paperless picking, are not just about keeping count of products; they represent a holistic approach to warehouse management. By harnessing the power of inventory software, product sellers can achieve unprecedented levels of accuracy, efficiency, and customer satisfaction.

As the digital transformation of inventory management continues to evolve, those who embrace these solutions position themselves at the forefront of their industry, ready to meet the challenges of a rapidly changing market landscape. With the right inventory solutions in place, businesses can unlock their full potential and thrive in the competitive world of product selling.