Streamlining Inventory with Management Software

In my two decades of writing, I’ve seen warehouses revolutionize efficiency with management software. Central to this is the understanding that inventory and warehouse systems differ yet intertwine. While one keeps goods flowing smoothly without surplus, the other organizes space and movement in a facility.

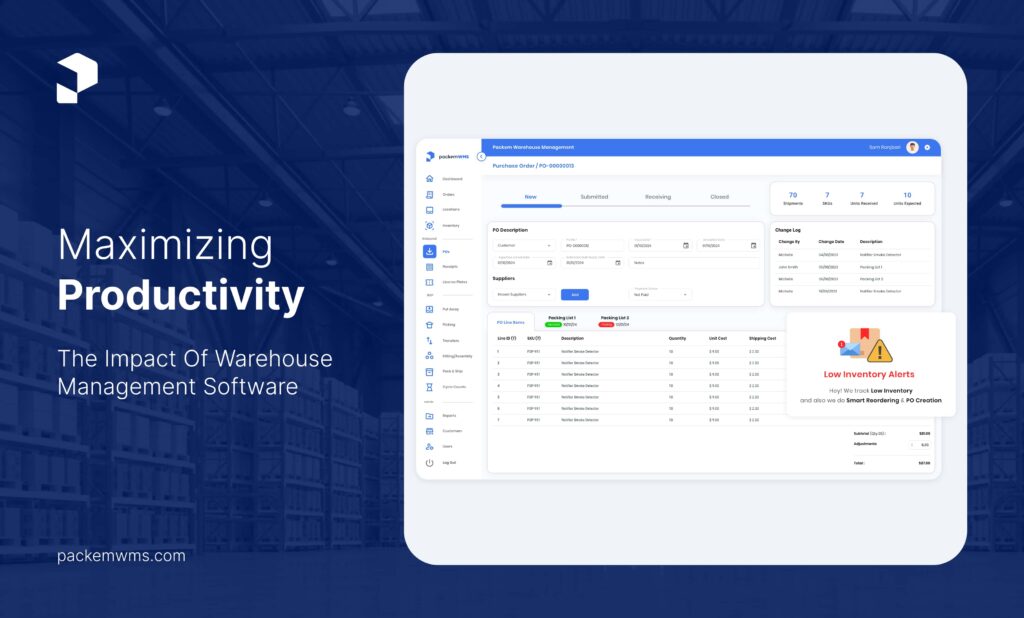

Nowadays, we harness software for both roles—ensuring products are tracked from arrival to shipment accurately. This digital shift means less chance of error than when tasks were manual. We look for features like easy stock tracking or alerts so nothing falls through the cracks.

Warehouse workers now use scanners linking directly back to our central system – it’s seamless coordination at its finest!

Barcode Systems Enhance Tracking Efficiency

Barcodes are a must in smart warehousing. They let us track every item with ease, from getting goods to sending them out. Picture this: A worker scans an item; right away, our system knows where it’s and updates the list.

Way fewer happen now because manual checks aren’t needed as much – we trust our tech! It doesn’t stop there either. Imagine needing something from high shelving—in seconds, after scanning its code, machinery gets moving to fetch it for you.

Costs go down too since we don’t need lots of individuals on hand just entering numbers or picking through stock by eye. Clear benefits show up fast—our barcode scanners peel back layers of complexity making simplicity shine in tracking vast goods inventories quickly without blunders that cost time and money.

Optimizing Layout for Faster Operations

In optimizing a warehouse layout, every inch counts. Think about it like this: the way items are placed matters big time. You want to put things where they can be reached fast and easy – especially stuff that moves quickly or has got an “eat me first” date stamped on them.

Because you don’t want anything going bad and getting tossed out. Now, heavy stuff shouldn’t sit up high because if something goes wrong, boom – there’s trouble right there! Safety’s huge in our line of work; tight spaces for driving around those massive lifting trucks aren’t cool at all – accidents waiting to happen.

And then consider growth — smart arranging means maybe skipping the cost of splashing cash on new digs. Tiny changes add significant room when stacked shelf by shelf! Lastly, everyone wants their order yesterday!

So layouts must let pickers zip through with no fuss — happy customers make everything run smoother.

Integrating Software and Hardware Solutions

We need to fuse our software with the right tools. Picture handheld computers that workers use every day, all across our floors. They capture data fast – from barcodes on boxes to ID tags for gear.

Now imagine this info flowing seamlessly into your warehouse program’s brain; it knows what’s where and how much in real-time. Printers matter too- the ones spitting out labels or receipts can talk directly to your system, no extra steps needed. Cue better asset tracking and less time wasted.

It reads multiple tags at once without a direct line of sight—this means instant updates on heaps of items together, not one by one. Software makes these devices sing along: mobile apps driving down costs while printers hum quietly behind scenes thanks to smart manage programs minimizing downtime when they hiccup.

All pieces tied tight by location technologies ensure nothing gets lost or missed as you move goods around like clockwork inside your space.That integration isn’t just fancy—it’s crucial for keeping things up-speed and dead-on accurate in today’s faster-than-ever world.

Real-Time Data for Better Decision-Making

Real-time data from Warehouse Management Systems (WMS) is a game changer. It gives us instant insights into stock—what we’ve got, where it’s at, and how much moves through day to day. This knowledge lets us manage inventory better; decisions on restocking get smarter because they’re based on solid facts.

We can also see orders as they happen which means we fill them faster and more accurately than ever before. Errors drop — way down — because everything gets tracked in the moment with barcode scanning or RFID tech. No guesswork: just precise movements leading to happier customers who get what they ordered when expected.

Overall, these systems let businesses adapt fast by showing exactly where adjustments should be made for operations to run smoothest. Better productivity without wasted effort keeps our costs lower too – that’s critical in today’s tight marketplaces.

Experience the simplest inventory management software.

Are you ready to transform how your business does inventory?

Automating Tasks with Advanced Warehouse Technologies

Inside the bustling world of warehouses, we’re seeing a revolution. It’s all thanks to automation technologies that merge AI smarts with solid gear. We’ve come far from days when manual checks ruled inventory management—now it’s robots doing the heavy lifting with incredible accuracy.

We use barcodes and RFID tags; they work like magic for tracking our stock without slips or delays. Real-time data isn’t just jargon—it streamlines everything so we keep up with demand smoothly. Order fulfillment too has gotten speedy, accurate as can be.

No more slow sorting by hand; machines do it quicker than you’d believe! This means happy customers getting their things fast—and sticking around because of this trusty service. Robots handle it now—injuries in workers go down cause there’s less strain on them day-to-day.

Safety is key here—we look out for each other while tech takes care of the rest. And think about individuals at work—they get to dive into roles where brains beat brawn any time—a real bonus for morale plus career paths open wide! I know these upsides well—I’ve seen how they transform places I visit as part of my writing job exploring warehouse wonders!

Boosting Productivity Through Analytics Tools

Using analytics tools for warehouse management sharpens our work every day. We see where items live and move them out fast, with few mistakes along the way. This smooths things out from start to finish.

Good storage means more gets done at less cost, yet we keep quality high; this pleases people who buy what we sell. They come back for more because they like how quick and right their orders are filled each time. We track all that’s stored so well it’s hard not to find it when needed – no wasted time or space here!

Our teams do better as processes get sleeker which lets us answer quickly when customers call. Data guides us in making smart changes often to stay ahead while cutting down on costs caused by errors or slow-moving goods More sales without bigger messes mean success grows even easier over time! Warehouse management software revolutionizes efficiency.

This tech streamlines inventory, speeds up order processing, and sharpens accuracy in fulfillment operations. With a system like PackemWMS at the heart of your warehouse, you see real-time data that helps make smart decisions fast.

Teams work better together; products flow smoothly from shelf to shipment. Embracing this powerful tool means doing more with less time – taking productivity to new heights while cutting costs along the way. Say hello to leaner operations and goodbye to wasted hours with an expert solution by your side.

FAQ's

Warehouse management software enhances productivity by streamlining inventory processes, optimizing layout, integrating with hardware, providing real-time data, automating tasks, and utilizing analytics tools.

Key features in inventory management software include easy stock tracking, automated alerts, seamless integration, barcode scanning, and real-time data updates, ensuring efficient operations.

Barcode systems enable quick and accurate item scanning, reducing manual errors and saving time. Compared to manual methods, they lower costs and improve efficiency.

Optimizing warehouse layout involves easy accessibility, safety prioritization, space maximization, and proper storage of heavy items, leading to faster operations and reduced space requirements.

Integrating software with hardware facilitates seamless data capture and communication, aiding faster decision-making. Real-time data provides accurate insights into inventory, while automation and analytics tools improve efficiency and safety.