Efficient inventory management is a critical aspect of running a successful warehouse operation. EDI integration plays a vital role in automating and streamlining inventory-related processes.

EDI integration refers to the exchange of electronic business documents, such as purchase orders and invoices, between different systems within a warehouse management software ecosystem.

It enables seamless communication and data exchange between suppliers, vendors, and the warehouse management system itself.

Some of the common types of code transactions you hear when talking about EDI are:

- 850 : Purchase Orders

- 855 : Acknowledgment of Order

- 856 : Advance Ship Notice

- 810 : Invoice Sent to Buyer

PackemWMS has developed partnerships with SPS-Commerce and Techdinamics Integrations to support EDI and API integrations for any ERP and third-party software. SAP, NetSuite, MS Dynamics, and Walmart are the few systems we have integrated with successfully.

How Does Packem Handle EDI?

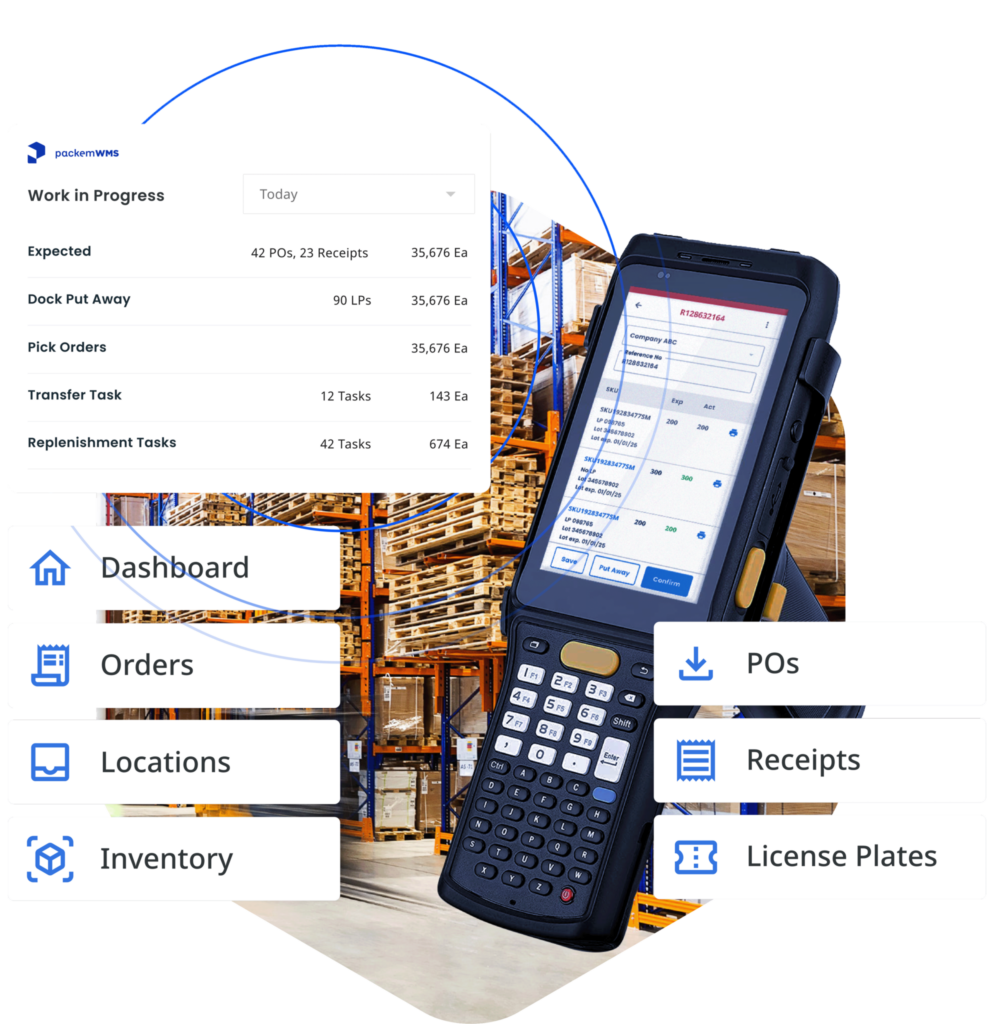

PackemWMS is a cloud-based inventory management system that offers Electronic Data Interchange (EDI) integration as one of its features. EDI in Packem works to streamline the communication process between businesses and their suppliers, customers, or third-party logistics providers. Here’s how Packem typically handles EDI:

Integrated EDI: Packem integrates EDI directly into its inventory management system. This means users can manage their EDI transactions within the same system they use to manage inventory, sales, and purchases.

- Automation of Transactions: EDI in Packem automates key transactions, such as purchase orders, invoices, and advanced shipping notices. This reduces manual data entry, minimizes errors, and speeds up the processing time.

- Compliance: EDI feature is designed to meet the compliance requirements of major retailers and trading partners. This ensures that transactions adhere to the specific formats and standards required by different partners.

- Real-Time Visibility: With EDI integration, users gain real-time visibility into their supply chain. They can track orders, confirm deliveries, and update inventory levels automatically.

- Scalability: As a company expands its trading network, Packem can handle an increasing number of EDI transactions.

- Customization: Packem allows customization of EDI workflows to suit specific business needs, which can be particularly beneficial for businesses with unique processes or requirements.

- Support and Maintenance: Packem provides support for the setup and ongoing maintenance of EDI connections, ensuring that any issues are resolved quickly and that the system remains up-to-date with evolving EDI standards and technologies.

In summary, PackemWMS approach to EDI is to integrate it seamlessly into their broader inventory and order management system, aiming to improve efficiency, accuracy, and compliance for businesses engaging in electronic data exchanges with their trading partners.

Experience the simplest inventory management software.

Are you ready to transform how your business does inventory?

Benefits Of EDI Integration For Enhancing Efficiency And Accuracy

Streamlined Order Processing: With EDI integration, manual data entry and paperwork are minimized, reducing the chances of errors and delays. Orders can be processed faster, resulting in improved customer satisfaction and faster order fulfillment.

Real-Time Inventory Visibility: Real-time visibility into inventory levels, allowing warehouse managers to make informed decisions regarding stock replenishment, order prioritization, and resource allocation. Accurate and up-to-date inventory information helps optimize supply chain operations.

Automated Data Exchange: EDI integration eliminates the need for manual data entry by automating the exchange of documents and information. This significantly reduces the chances of human error, improves data accuracy, and saves time.

Finding The Right Tools For Effective Inventory Management

There are various warehouse management solutions available in the market, offering features such as inventory tracking, order management, and reporting capabilities. When deciding between what software to implement, be sure it’s easy to use and simple to train your staff. Not all WMS solutions offer seamless EDI integrations, so be sure to seek one if that’s something you require today or in the future. Read more about our recent trip to Pet EXPO 2023

Barcode Scanners: Wireless barcode scanners enable efficient and accurate scanning of product barcodes, facilitating inventory tracking and management. Barcode scanning apps and Bluetooth-enabled scanners further enhance mobility and convenience.

Cloud-Based Inventory Management Systems: Cloud-based solutions allow businesses to store and manage inventory data securely on remote servers. This enables real-time access to information from anywhere, facilitating collaborative inventory management and scalability.

Conclusion

Efficient warehouse management is crucial for businesses to thrive in today’s competitive landscape. By embracing EDI integration and leveraging scanners, businesses can streamline operations, improve accuracy, and enhance overall efficiency. Investing in the right warehouse management software and integrating it with EDI capabilities will enable businesses to stay ahead and meet the ever-growing demands of their customers.

Remember, finding the best software for your specific business needs is essential. Take into consideration factors like customer support, integration capabilities, and ease of use when selecting an inventory management solution. With the right tools and a well-integrated system, you can optimize your warehouse operations and achieve greater success.

Learn more about our rapid on-boarding of WMS to any size operation