Are you concerned about the precision of your inventory? Do you want to stay updated with the changing supply chain requirements and regulations? You need a Warehouse Management System to address these problems and create a real-time and reliable environment.

WMS quickens the management of inventory by reducing the inventory levels and order cycle time. It is designed to regulate all your warehouse activities and tracks every unit down to every minute detail to attain inventory accuracy. In other words, WSM makes inventory management faster, more efficient, and easier.

Challenges faced by 3PLs while achieving their client order on time

- In the absence of automated software for billing, 3PLs face a loss of revenue due to their inability to get the invoices for the services they offer.

- It is difficult for a 3PL to manage returns as it demands a team of experts and resources. Higher volumes of order returns lead to more expenses.

- It is challenging to manage inventory across multiple channels.

For a supply chain to be successful, third-party logistics are crucial. Amidst the shortages and disruptions in the current supply chain, 3PLs need inventory management software that completes orders.

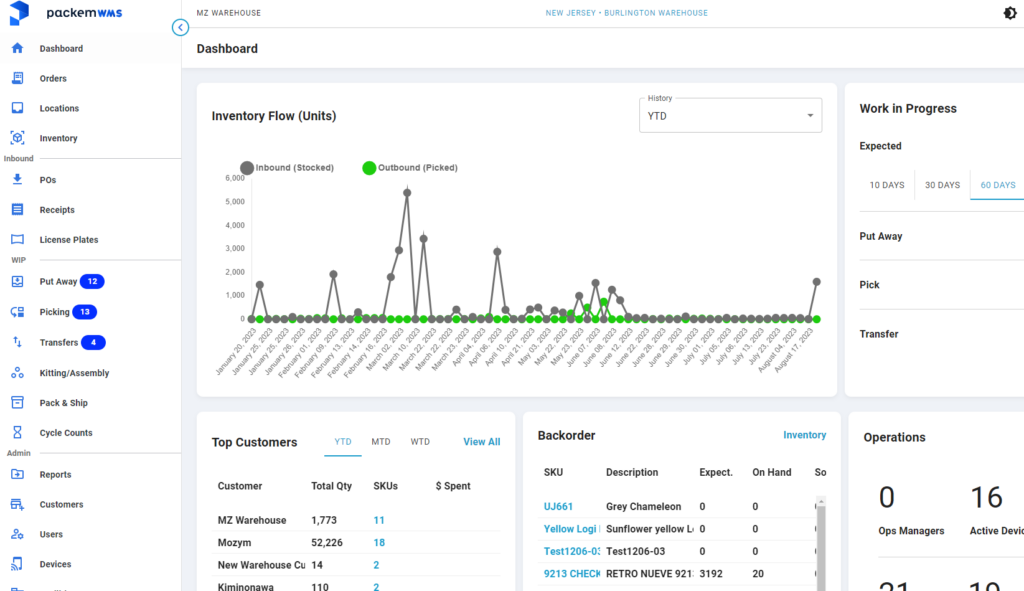

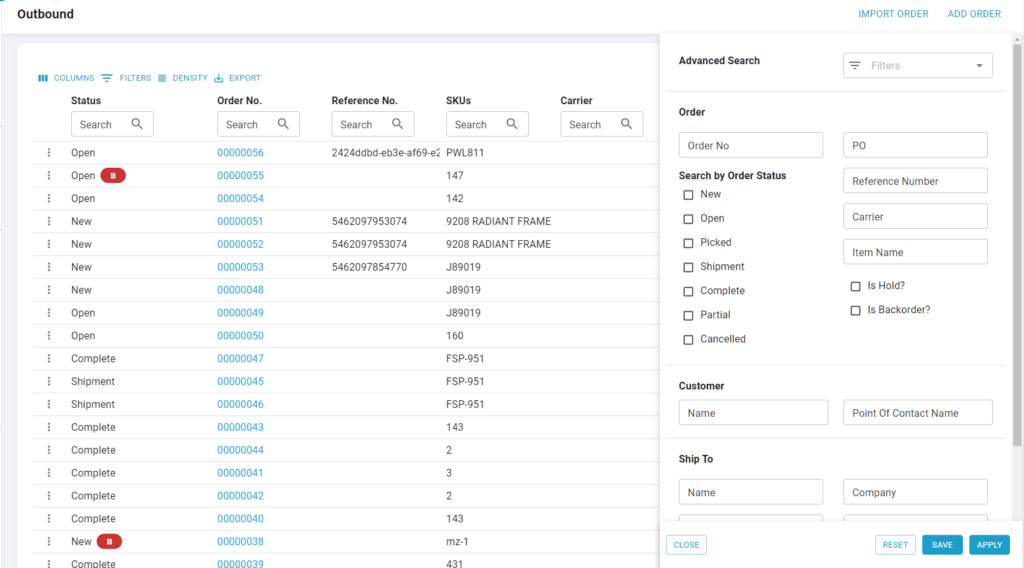

3PLs need a warehouse management system that provides efficient order management in one interface. It is a vital tool for third-party logistics to effectively manage warehouse operations. This software smoothly integrates with the infrastructure and helps manage various operations including order fulfilment and shipping. The staff can get to know about the order movement right from the time it arrives to its delivery.

Let us dive deeper into how the right WMS handles the warehouse operations for 3PLs –

1. Billing

Being the most important feature of WMS, it allows providers to create personalized billing profiles, automatically generate invoices, and obtain client-centric transactional data. As it manages billing in a single interface, 3PLs can ensure that their billing is error-free and time-saving as well.

2. Inventory handling

3PL Warehouse Management System efficiently manages client’s inventory by having complete visibility of the inventory that includes location, inventory that is to be stocked or allocated, and more.

3. Managing locations

3PL providers must manage locations to cater to the unique requirements of each client. With the use of WSM which can define dry storage, buffer zones, dry storage, and more, 3PL providers can ensure that they can make maximum use of their warehouse space to fulfil the requirements of their clients.

4. Easy integration

The WSM for 3PLs ensures hassle-free integrations with different business software platforms as you do not have to purchase the rights to have access to multiple new apps just to add WSM.

5. Real-time tracking

The Warehouse Management System for 3PL enables customers to track orders in real-time through a web portal that is not just confined to employees. This portal helps customers deal with the return process and provide feedback.

Once you incorporate WSM, you will wonder how you managed without it! This inventory management software reduces errors and quickens efficiency by tracking work progress in real time.

Experience the simplest inventory management software.

Are you ready to transform how your business does inventory?

Essential features to look for in a 3PL WSM

1. Ready-to-use integrations

Suppliers use WSM to inform 3PLs about their inventories and orders. Additionally, they want to have visibility of the movement of their inventory. Having ready-to-use integrations will help information transfer in no time without the need for any manual intervention. The easy integration of WSM with ERPs allows 3PL providers to synchronize inventory, create purchase orders, and receive consignment details.

2. Excellent client onboarding

An effective WSM must enable a smooth client onboarding process. Client onboarding allows their operations to go live as soon as possible. Moreover, a WSM for 3PLs must provide each client access to the account so that they can check the condition of the operations.

3. Order returns

Suppliers expect 3PLs to have the capabilities and right arrangements for order returns. However, they have to face difficulties when there are multiple order returns. WSM must enable a steadfast workflow and a receiving process for order returns.

4. Seamless implementation

Whether it is the first time or migrating from the existing system, WSM implementation must be seamless. The whole process must be accessible with a quick information transfer.

It is a daunting task to choose the right software with multiple options available. However, an insight into the essential features of a WSM for 3PL can streamline the process for you. The key to finding the right WSM is understanding the needs of the clients and selecting one that caters to their demands.

Go for a custom 3PL WMS for your warehouse. Why?

Smooth integrations: Custom 3PL WMS ensures seamless integrations, allowing information transfer across multiple platforms without the need for manual data entry.

Optimized workflow: Get streamlined warehouse operations with custom WMS. It ensures efficient management of inventory, logistics, and order fulfilment.

Real-time visibility: Provide comprehensive and real-time data insights into warehouse operations. Equipped with tools such as Machine Learning, and analytics and reporting tools, WSM facilitates informed choices for best resource distribution.

Cost-efficient: Given the tailored functionalities, custom WMS is more cost-effective in the long run. Additionally, these systems are maintained by vendors, thus removing the maintenance costs.

To Sum Up

To sum it up, choosing the ideal WMS software involves a careful evaluation process to sync the capabilities of the system with the unique needs of your organization. You need to consider all the factors while making this critical decision.