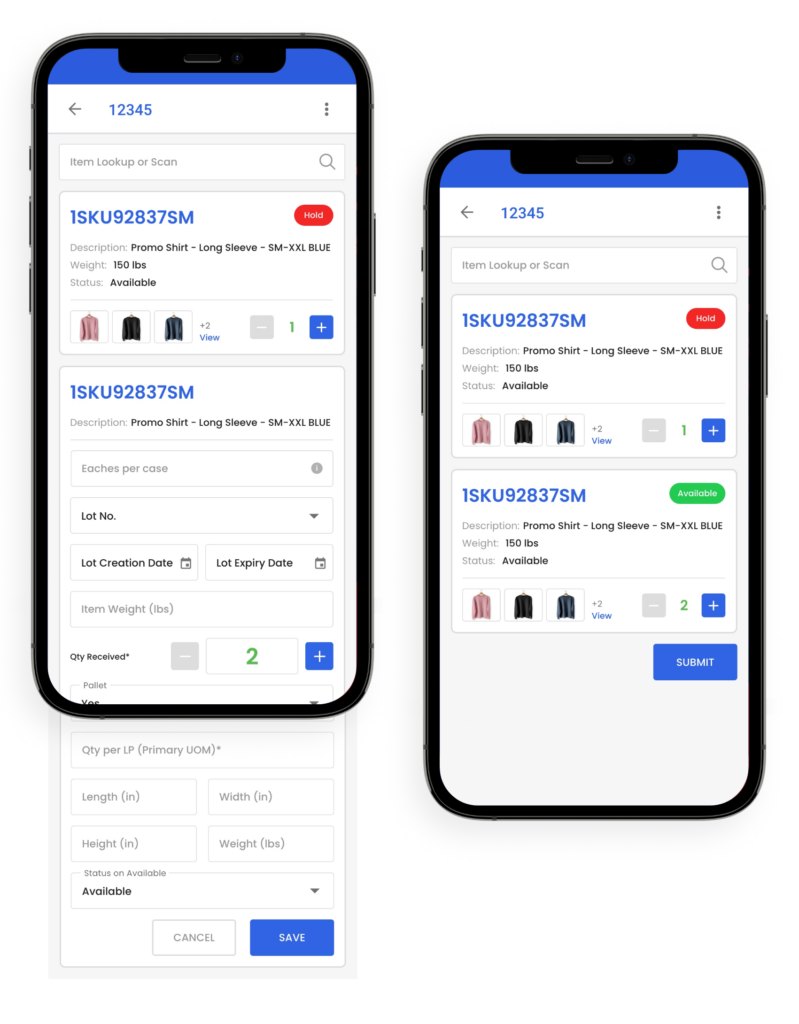

1. Scan Everything

Incorporate scanning at every step. The more you scan, the less mistakes you make. It might hear from your staff that it’s too much work to scan bin locations and products, but the goal is to keep an accurate inventory and reduce errors.

Use barcodes or RFID tags to track inventory, from the moment it arrives until it leaves. Scanning ensures accuracy in inventory management, leading to fewer errors, less waste, and improved customer satisfaction.

2. Choose The Right Software Partner In Your Warehouse Inventory Management

You should select a technology partner when searching for a robust WMS. Most warehouses don’t have an IT team, so you want to ideally select a team that is knowledgeable and can be a good consultant to you as your grow your business.

Look for a provider who offers not just software but a partnership. They should understand your business complexities and offer solutions that grow with you. A good partner will provide continuous support, updates, and training. They can even help you with onboarding of your customers.

3. Integration! Integrations!

Your Warehouse management software should easily integrate with other systems you use, for shipping, EDI, and e-commerce. Integrations reduce the need for multiple software solutions and minimizes complexity and training across your business.

PackemWMS is a warehouse and inventory management system that includes all you need in one platform:

- Shipping Carriers: Integrates with EasyPost for printing shipping label, requiring signature, and rate shopping

- E-Commerce: Packem directly integrates with Shopify, and Shipstation, and indirectly with many other e-commerce platforms, so it’s all seamless for you.

- Accounting: Direct connection to QuickBooks and Xero so all invoicing, inventory, PO, and customer data is mapped and pushed to your accounting system.

- EDI Support with the help of our partners in SPSCommerce and TrueCommerce.

4. Appoint A Competent Warehouse Manager

Great software, integrations, and scanning is all great, but you need a buy-in from your staff. The warehouse manager’s role is pivotal to achieving that. Ensure they are not only experienced in managing physical inventory and operations but are also adept at using and optimizing the WMS. Their decision-making and leadership directly influence the efficiency and productivity of your warehouse.

Experience the simplest inventory management software.

Are you ready to transform how your business does inventory?

5. Automate. Set It And Forget It

Aim for a WMS that offers extensive automation capabilities. At the end of the day, you want to use software so it can automate repetitive tasks, and make decisions for your warehouse based on set rules.

Automation ensures that critical decisions in the picking and packing process are made by the software, based on real-time data and predefined rules, reducing human error. This leads to faster operations, better resource utilization, and more consistent outcomes.

A few examples of automation are:

- Add a signature requirement on the package if the order is above a certain amount

- Force shipping with a certain carrier(s) based on the order source. Meaning, if the order came from Shopify or B2B.

- Set packaging rules based on a product or number of products in the order

- Or your own custom rule!

6. Conduct Regular Audits

Regularly audit your inventory to verify the accuracy of your records. This helps in identifying discrepancies early, managing shrinkage, and ensuring that the stock levels are maintained accurately. Scheduled cycle counts are a great way to do physical counts of picking locations.

7. Optimize Warehouse Layout

The design of your warehouse significantly impacts the efficiency of operations. Consider adopting L-shaped, U-shaped, or I-shaped floor plans that are known for facilitating a smooth, free-flowing movement of inventory. Ensure that the design you choose complements the nature of your inventory and business needs.

The Bottom Line

Effective warehouse inventory management is about more than just storing inventory; it’s about strategically managing it to improve overall efficiency and productivity. By implementing these strategies and effectively using WMS, you can ensure smooth operations, reduce costs, and keep your customers happy.

Checkout this great resource for Inventory Solutions for Product Sellers: Stock Management in Real-time