"From Raw to Finished

Goods"

Manufacturing Made Easy with PackemWMS

Manufacturing Made Easy with PackemWMS

"From Raw to Finished Goods"

Manufacturing Made Easy with PackemWMS

Manufacturing Made Easy with PackemWMS

Transform your food production with a software solution built for speed, accuracy, and control.

PackemWMS’s Food Manufacturing Software is designed to help you manage raw materials, production processes, inventory, performance, and integrations — all from one powerful platform tailored specifically for the food industry.

Why Choose PackemWMS for Your Food Manufacturing Business?

Our solution is designed with the challenges of food production in mind — from traceability and compliance to multi-unit inventory control and performance management.

Key Benefits:

- Designed specifically for food production and packaging workflows.

- Helps meet industry standards for traceability, safety, and quality control.

- Reduces manual errors and increases order fulfillment speed.

- Scalable for small operations or large, multi-location manufacturers.

Things you can manage

Raw Material Management for Production Teams

Simplify the way your production team handles raw materials from the moment they arrive.

Whether you’re dealing with cases of meat or pounds of spices, PackemWMS gives you full control and flexibility:

- Receive raw material purchase orders (POs) in cases, pounds, or other measurement units.

- Easily place and manage Bills of Material (BOMs) to transform raw ingredients into finished products.

- Pick ingredients from multiple warehouses or storage locations to ensure efficient and accurate batch production.

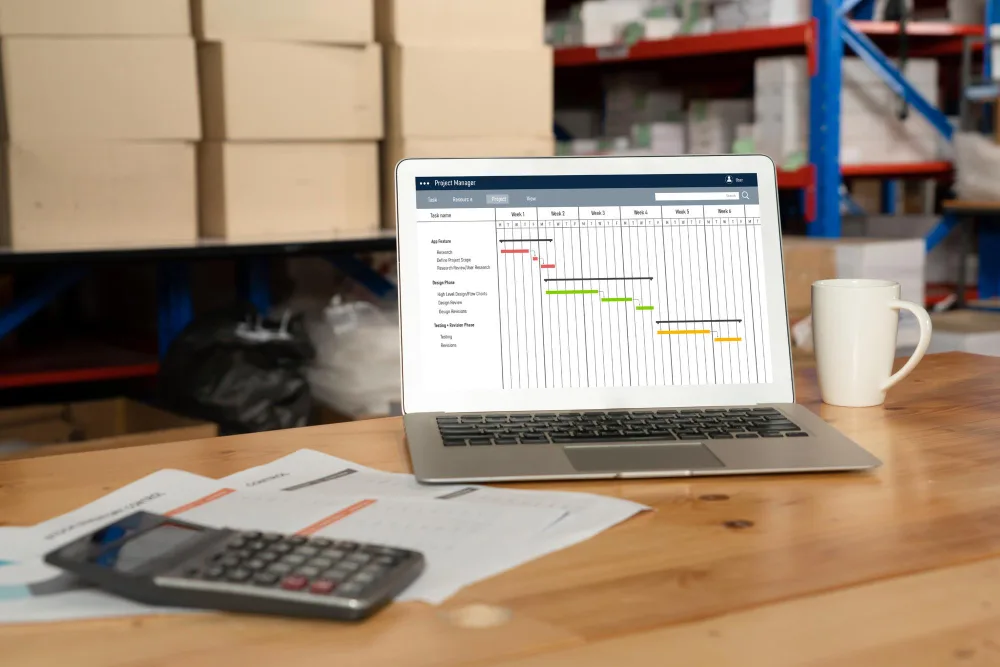

Powerful Integrations to Boost Efficiency

- QuickBooks Integration for accurate financial tracking and reporting.

- Sync with popular eCommerce platforms to process online orders without delay.

- Integrate with your existing ERP system to create an end-to-end digital workflow.

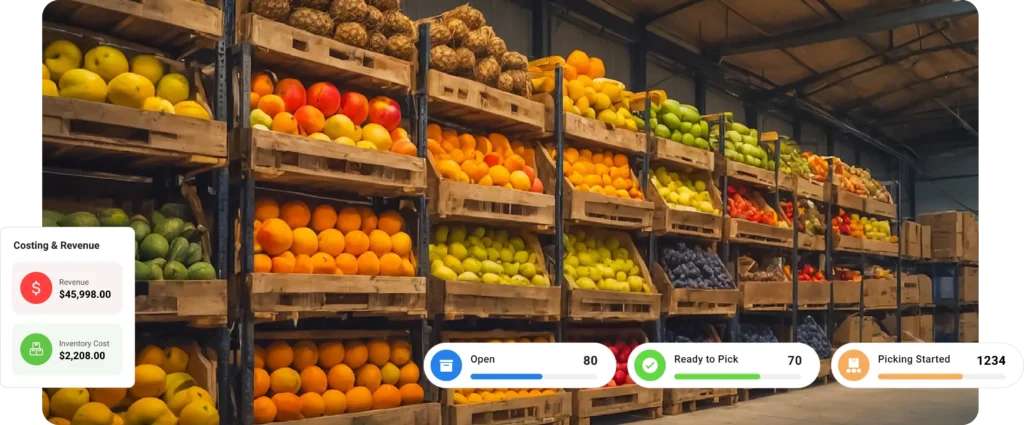

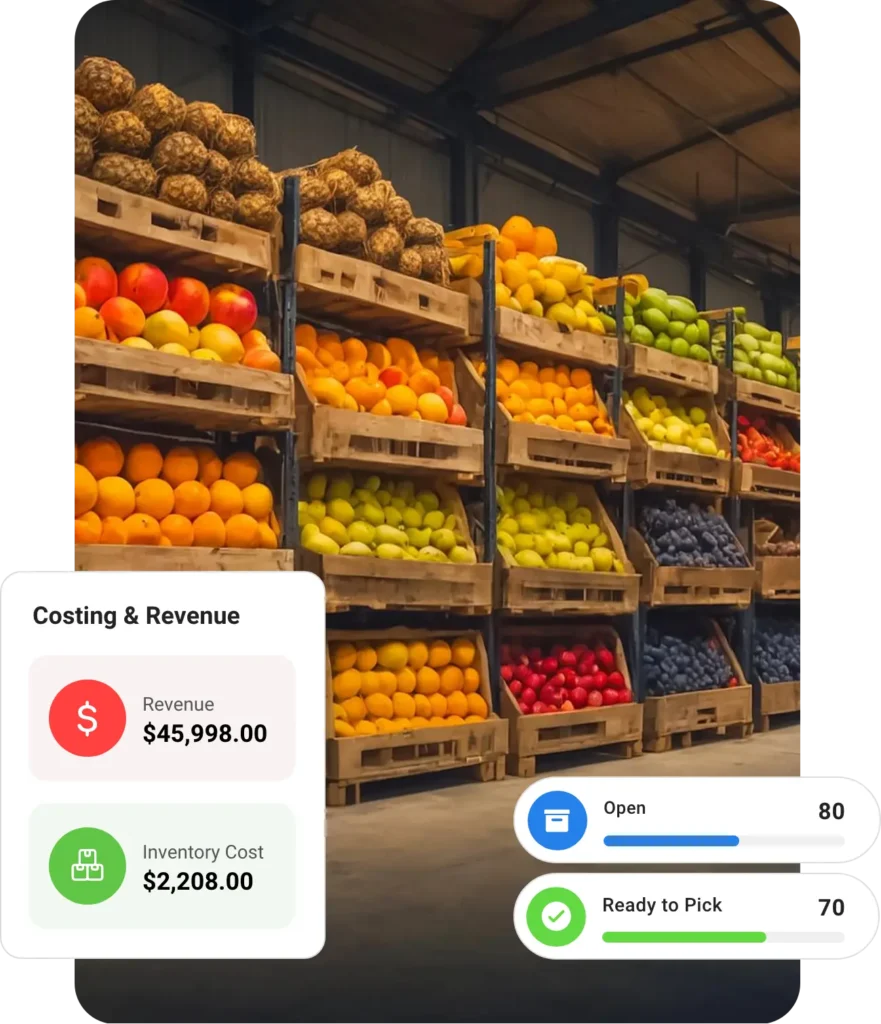

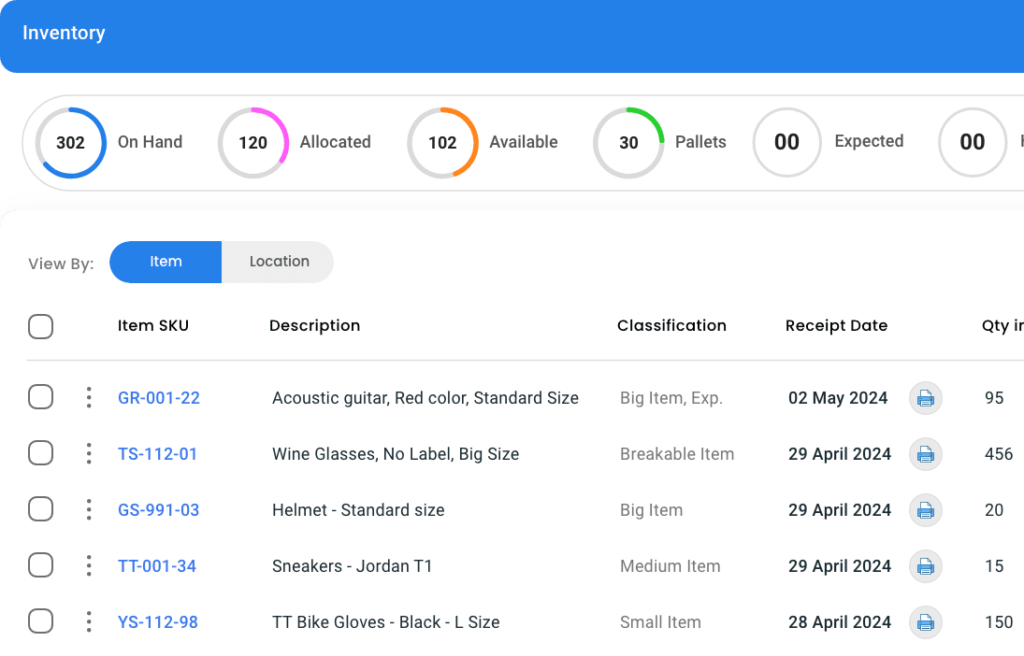

Inventory Management Made Easy

Food manufacturers need precise, real-time inventory visibility. PackemWMS ensures your team can manage and move stock efficiently.

- Track inventory in various formats: cases, pounds, bags, units, and more.

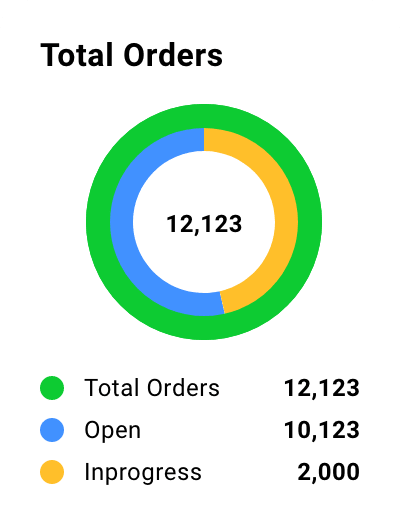

- Stay organized with a centralized order management system that works across production and distribution.

- Pick, pack, and ship products with speed and accuracy to fulfill customer and retail orders on time.

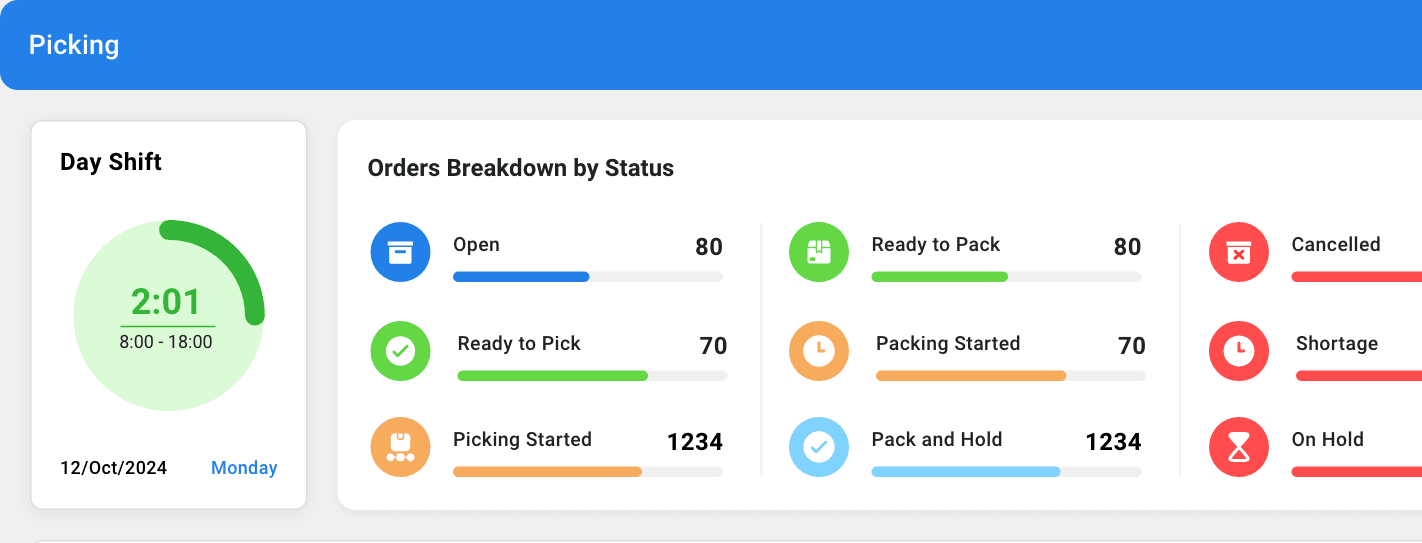

Performance Tracking and Operator KPIs

With PackemWMS, you can:

- Track operator performance in real-time, including pick and pack rates.

- Identify bottlenecks in your process and improve task allocation.

- Use data-driven insights to boost overall warehouse productivity and reduce downtime.

Frequently Asked Questions

How does PackemWMS help with traceability in food manufacturing?

Our software allows complete end-to-end traceability from raw materials to finished goods. You can track batches, lot numbers, expiry dates, and supplier information, ensuring quick and accurate recalls if needed.

Can I monitor production and inventory levels in real-time?

Yes. PackemWMS offers real-time inventory tracking, production status updates, and stock level monitoring so you can make informed decisions instantly.

Can it handle expiry date and batch control?

Yes. The software enables you to manage expiry dates, first-expiry-first-out (FEFO) picking, batch tracking, and alerts for approaching expiration.

Does PackemWMS support multi-location food production and storage?

Yes. Whether you operate a single facility or multiple production and storage sites, PackemWMS can manage all your locations under one system.

How customizable is the software for my unique food production process?

PackemWMS is highly customizable. We understand that every food manufacturer has unique workflows, and our software can be tailored to fit your specific needs, including custom workflows, user roles, and integrations.

What kind of support and training does PackemWMS offer?

We provide onboarding, training sessions, and dedicated customer support to ensure your team can fully utilize the software. Ongoing support is available via chat, email, and phone.

How do I get started with PackemWMS for my food manufacturing business?

Simply contact us through our website or request a free demo. Our team will walk you through the setup and help customize the system for your operations.

Manufacturing Made Easy with PackemWMS

Manufacturing Made Easy with PackemWMS